TOOLTRONICS 探针

In 1995 we made the decision to begin designing and manufacturing custom test sockets for the power electronics and aerospace relay industries. One of the main components, needed, was Kelvin pins. Initially, we planned to purchase them from one of the established suppliers, but after much research were unable to find a suitable candidate.

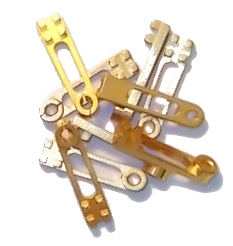

TOOLTRONICS Custom Contacts

In addition to our popular ‘LPK’ series of kelvin contacts, Tooltronics has designed and manufactured several other types of contacts:

HPK kelvin series: These low insertion force contacts are rated at 50A and are ideal for the high current positions in a typical test socket. These contacts are available for the following module pin diameters: .040″, .062″, .080″, .150″ and .180″

HPK-FS series: These contacts are rated at 50A and were designed for use in our kelvin ZERO INSERTION FORCE (ZIF) sockets. To compensate for the lack of wiping action in a ZIF socket, the face of these contacts is serrated for an improved electrical connection. These contacts are available for the following module pin diameters: .025″, .040″, .062″ and .080″

HPK-PCB series: PCB mountable high current contacts are used in burn-in and test applications. These contacts are available for the following module pin diameters: .031″, .040″, .062″, .080″, .150″ and .180″

MPS series: High current solid pin non-kelvin contacts are used in vibration sockets and other applications where kelvin is not a requirement. These contacts are available for the following module pin diameters: .031″, .040″, .062″, .080″ and .094″.

TOOLTRONICS Kelvin Pins

The Kelvin pins needed three features:

Precise orientation of the Kelvin pin is required when used in a relay socket for hook pins, which are often rotated 30°. Contacting square or rectangular pins also requires precise orientation.

High current is often required for power electronics test sockets.

To be able to retain the Kelvin pin’s vertical location, without the use of epoxy or other adhesives.

LPK-100 Kelvin Contact :

Data Sheet:

2.54 mm minimum centers

Contact Material: Brush Wellman Beryllium Copper alloy 25

Material Thickness: .015”

Heat Treatment: Full Spring Temper (after forming)

Finish: 30 micro inches Gold over 100 micro inches Boron Nickel

Insulator Material (Standard): 6/6 Nylon

Maximum Continuous Operating Temperature, 6/6 Nylon: 210° F (99° C)

Insulator Material (Optional): Ultem 1000

Maximum Current: 30 amps continuous (15 amps per side)

LPK-125 Kelvin Contact:

Data Sheet:

3.81 mm minimum centers

Contact Material: Brush Wellman Beryllium Copper alloy 25

Maximum Current: 30 amps continuous (15 amps per side)

Insertion/Extraction Force for .040” diameter pin with spherical tip: 10 oz.

TOOLTRONICS Surface Mount Test Sockets/Test Fixtures

The most economical Surface Mount (SMT) test socket is a clam-shell design which is contact populated with pogo pins. The customer can choose the socket material and the pogo pin type, including probe tip preference.

For production SMT testing, we recommend the TOOLTRONICS Micropress Test Fixture. The Micropress is a durable and precise fixture that will house the PERSONALITY MODULE (Contact Plate, Device Nest and Pressure Pad). The PERSONALITY MODULE is device-specific, so Micropresses can be re-purposed with a PERSONALITY MODULE change.

The TOOLTRONICS MicroPress

TOOLTRONICS Test & Burn-in Sockets

From our experience most test engineers have specific socket feature requirements, so most of our socket designs are custom.

Starting with the socket material, the customer can choose from several engineering plastics, including some that are ESD compliant. Socket size and socket mounting hole locations can be specified by the customer, as well.

Next, the customer can choose how the socket will be contact populated. For a typical high current application, the input and output power pin locations would be populated with the ‘HPK’ series kelvin contacts and the signal pin locations populated with the lower current ‘LPK’ series kelvin contacts.